|

|

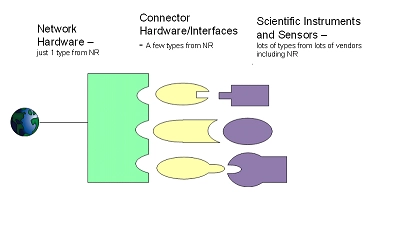

Networked Robotics' Technical Approach to Temperature MonitoringThe Networked Robotics approach to temperature monitoring is different from that of our competitors. Where competitors often use a single type of networked sensor, we collect data from many different environmental and electronic sources in many different ways. We believe that the method of connectivity to the instrument is more important than the network technology used to relay the acquired values to data collection servers. With Networked Robotics' architecture you can use whatever method of standard network connectivity, wired or wireless, that you want. Where possible Networked Robotics uses no sensors, preferring to connect to those already in an instrument via data communication. 1) IntegrationThe Networked Robotics command to acquire temperature directly from a Thermo Fisher Scientific® incubator is "T". You can acquire temperature directly from a Chart Biomedical® MVE liquid nitrogen cryofreezer using the network-side command "T". You can acquire temperature directly from an older Harris® -80°C freezer using the command "T". You acquire temperature from a Networked Robotics digital temperature probe using the command "T" and on and on. The Networked Robotics hardware knows how to talk the complicated languages of each device type and convert that to a simple language on the network side. Networked Robotics integrates network data collection by providing a common language for diverse instruments from multiple vendors. The list of instruments we talk to grows constantly. The figure shows how this is accomplished in terms of the physical connections. Yellow and green are our hardware and purple represents scientific instruments and sensors from both Networked Robotics and third parties.

2) Digital Temperature ProbesWe are mostly digital. We must use in analog technologies in extremely cold or hot environments. In general as above - we prefer to acquire data directly from instruments. However some instruments do not have the capability of communicating digitally so we must collect data in a different way. Usually for this we use our digital temperature probes between -80°C and 100°C, In extreme environments we must use our analog probes that are served by our digital electronics. Our digital probes have advantages over analog probes. They have electronically embedded unique IDs to support calibration and regulatory compliance. They have very flat wire that passes easily through refrigerator seals. Analog wire is usually round and leaves a big air gap in the seal. They do not need to be adjusted. They can be run over long distances without the fear of compromise. They have processors in them that can do advanced things. When they are damaged they either work or don't work; they don't give slightly altered readings as do analog probes when subject to altered environments. They use less power and are more energy efficient. They have indicators that tell you that they are "logically" on, not just "physically" on. The LED tells you when it is set up right not just that it is plugged in. 3) The Network Monitoring Architecture and RedundancyThe Tempurity System's architecture for monitoring releases the power of high redundancy. When you think about it, if you were monitoring something really, really important to you, you would do whatever you could within the limits of your power to watch it. You would not just try to stand by it 24 hours a day, but you would sleep by it and you would probably get as many trustworthy people as you could to help you in case you fell asleep or fell ill or had to leave for any reason. You would get a backup to yourself, and then a backup to that backup. So that whatever happened somebody would always be there to protect that item against potential negative events 24 hours a day. The Tempurity System allows that capability. Redundant Tempurity System instances can be located anywhere on the planet. Essentially every networked computer in the world has the potential to monitor your item. You would probably tell your backups to let you know if for any reason they couldn't see the item. Let's say there was suddenly smoke in the room, or they were going to take a break, you would want them to let you know immediately of these non-watching events not after-the-fact. This is what Tempurity does. In some cases remote servers can not acquire data, but you are told immediately that they can't see it. 4) Temperature Monitoring and Everything Else MonitoringWe take the same approach to other parameters that we do to temperature. We collect humidity directly from scientific instruments, usually incubators, but also via our own digital sensors. We monitor RPM from shakers. We monitor the power in your wall outlets. We can monitor any analog sensor including those for light, rotation, pressure, position, and many other parameters using our voltage probe. We monitor liquid nitrogen level from cryofreezers and Co2 from incubators. And much more...... 5) Regulatory FeaturesNetworked Robotics supports features for advanced regulatory support including a full suite of regulatory tools This includes documents for installation qualification, testing and validation, and templates for your standard operating procedures. Our hardware has advanced features for regulatory use including electronically embedded unique IDs in our sensors so that probes can always be tracked in the calibration process. The software includes features that allow the notification of different people at different severity levels. See also our advanced regulatory package coming soon... 4) More Technical DetailsSee our document Six Rules for Network-based Data Collection for more technical details on how we attempt to solve complexity in scientific instrument data integration.877 FRZ TEMP ( 877 379 8367) 877 GLP TEMP ( 877 457 8367) |